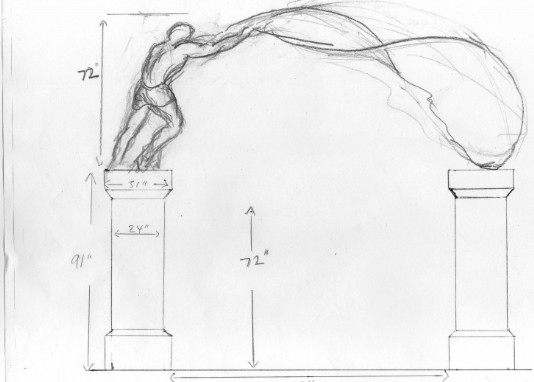

Making "Andrew the Fisherman"

Practical considerations with this sculpture involved placing a life-sized figure and large casting net in an exposed situation on pillars which link the city of Plymouth to the Minster Church, and structural considerations that were necessary in building an arch in which the figure would be made of bronze resin, and the net of stainless steel.

The first two images show the initial drawing and the clay maquette with a net made of woven aluminium.

Work on the life-sized figure commenced with an armature of steel, aluminium rod and wire-netting, as shown in the following gallery.

The next gallery shows clay being applied to the armature

resulting in the final clay figure.

The clay was then covered with a number of coats of silicon rubber into which seams were built for separation of the mould. A fibreglass support mould was then added, as shown in the next succession of pictures.

The mould was then removed, resulting in the desruction of the sculpture, which now existed only as a void within the sections of the mould.

The next gallery shows the cured rubber and the fibreglass supports. After the rubber had been located into the supports. bronze resin (a 50/50 by volume mix of bronze powder and polyestr resin) was poured into each section, followed by a backing coat using aother filler.

The construction of a bronze-resin sculpture is achieved in much the same way as in producing fibreglass boats or car bodies, so it is structurally strong.

In this instance however, because of added strains involved in creating an arch in an exposed location, I had all stress points reinforced with stainless steel plate and tube, as illustrated in this image of the inside of an arm and shoulder.

The sections of mould were then joined together, the whole piece washed down with acetone to remove surface resin, and then burnished using a steel brush on an electric drill, ready for chemical patination.

The net was made from tubular stainless steel and woven stainless steel netting. Graham Findlay, an accomplished sculptor in a variety of metals, who does all steel fabrication in my work, formed the shape of the net with me and did all the welding. To fix the netting to the "rope" required welds every 1/2 inch along a total length of some 20 feet. Quite a headache, as can be seen in the last picture of the followin gallery!

The completed sculpture was then transported to Plymouth and put in place by the experienced art intallation company Artful Logistics. The last gallery shows the installation and the sculpture finally in place.